We develop products using air molding technology

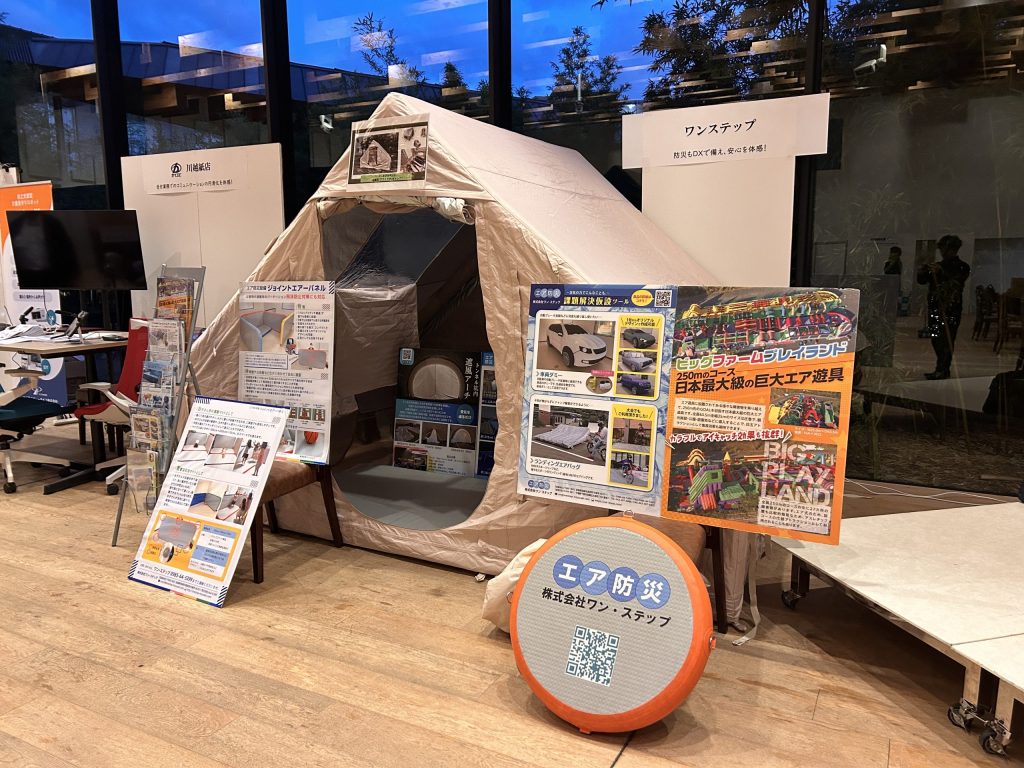

We develop disaster prevention and safety products using “air molding technology” that harnesses the power of air.

What is Air Molding Technology?

We are a Japanese company that develops disaster prevention and safety products using “air shaping technology,” which harnesses the power of air. Our products are lightweight and compact, allowing them to be quickly deployed when needed. They offer speed and flexibility not possible with conventional materials at disaster and emergency response sites.

Even for sites where standard sizes don’t fit, we can deliver original products at low cost and with short lead times.

Features

Air sculpting technology is the process of sewing together fabric to create three-dimensional objects, which are then inflated with air.

Our company has designed and manufactured inflatable play equipment such as inflatable floats, slides, and large pools made from vinyl for use at events where parents and children gather.

We began developing air sculpting products, inspired by the idea that we could use the air sculpting technology we’d cultivated to create products that are easy to store, portable, and expand by adding air only when needed, to help with disaster prevention and mitigation.

Products

Inflatable car dummy

This life-size vehicle dummy enables safe and easy automobile crash tests.

It allows for more realistic experiences and experiments such as evaluating automatic braking performance and educating drivers about road safety.

Its lightweight, compact design makes it easy to carry, and setup takes just 20 minutes.Its sealed design means no power supply is required once you’ve inflated it.It’s ideal for outdoor use or exhibitions where power is unavailable.

Fire Water Tank

This temporary water storage tank can be used for firefighting activities and to secure emergency water for daily life in the event of a disaster.

It can be set up in less than 15 minutes by simply inflating it, and can be stored compactly after use, taking up very little storage space.

We can accommodate capacities of 4,000L to 6,000L to meet the needs of fire stations. We can manufacture original specifications such as capacity, design, color, and size according to your requests, even from a single unit.

Company

- Company Name

- ONESTEP Co.,Ltd.

- Representative

- Hiroyuki Yamamoto

- Establishment

- June 2002

- Outline of Business

- Development, sales, and rental of equipment for disaster prevention, disaster mitigation, infection control, and medical use

- Location

- 4625-1 Imaizumi-ko, Kiyotake-cho, Miyazaki-shi, Miyazaki 889-1602, Japan